TWMC high-speed synchronous machines feature a time tested and

proven rotor construction design. For high torque transmission

throughout its variable speed range, the rugged construction of

these premium rotors are without equal.

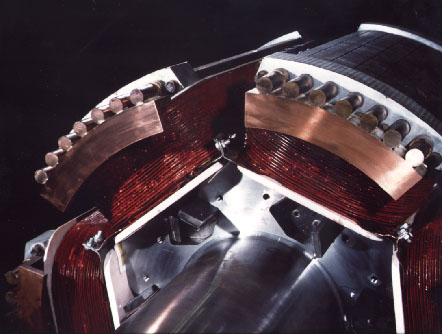

The rotor construction starts with a high strength alloy steel

shaft forging that is precision machined, ground and finished

to our exact tolerances. Next the rotor spider is constructed

from massive steel laminations and machined to mate with the shaft

to form the rotor core assembly. Dovetail slots are then milled

into the spider to accept the dovetailed pole pieces that are

secured in place by tapered keys. Dovetail pole construction (pictured

below) ensures a secure attachment to the shaft and spider.

Rotor poles are stacked from thin laminations bolted together

to form the pole pieces. Field coils are edge-bent and strap wound,

then insulated with a custom-designed thermosetting turn insulation

system before being installed onto the rotor poles. Coils are

staggered to allow for efficient heat transfer and are solidly

braced at the final assembly stage.

Amortisseur windings use copper/copper alloy damper bars and

segments. A shaped copper interconnect between adjacent poles

alleviates thermal stresses which occur during starting.

» Request

a Quote for a custom engineered product!